About Company

Seamless & Efficient Product Design for Precision Manufacturing

At MG Techworks, we specialize in plastic injection molding, custom plastic product design, and engineering solutions to bring high-quality, precision-engineered products to the market. Our expert engineers and designers work with advanced CAD software, Autodesk tools, and cutting-edge automation design technologies to ensure manufacturability, durability, and cost-efficienc

Our Works

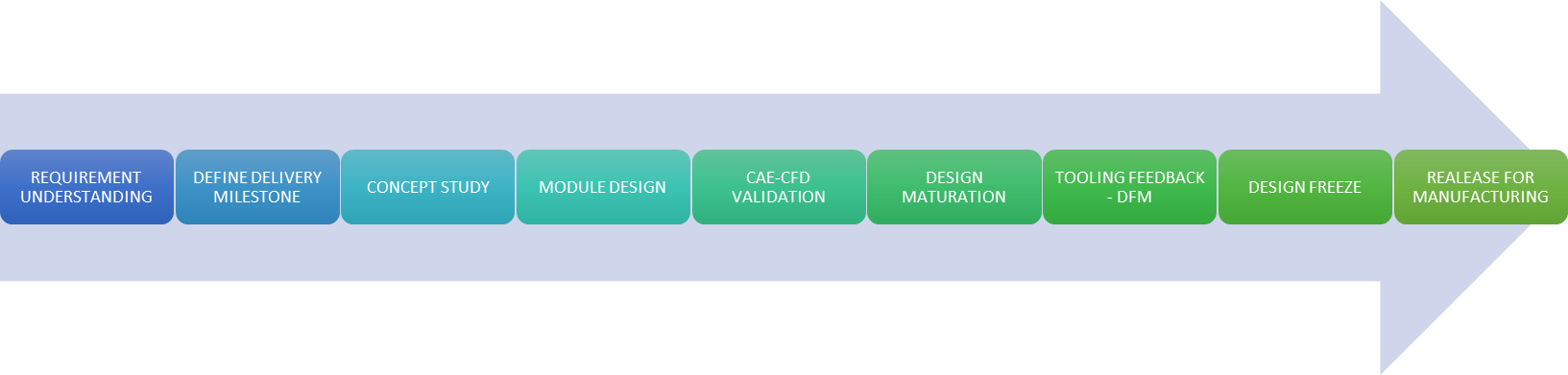

Product Design Process

The product design process is a structured approach to creating a product that meets user needs and business goals while also considering technical feasibility and market trends. Here's a general overview of the key stages in the product design process:

Key Stages of Product Engineering:

Why Us

Global standard Services

Timely delivery in product design and manufacturing is essential for project success. It guarantees that the product reaches the market as scheduled, helping businesses stay competitive, optimize supply chain efficiency, and meet customer expectations while ensuring seamless production workflows and high-quality manufacturing solutions

Building strong relationships is vital for success in the product design and manufacturing industry. Establishing trust and expanding your professional network leads to long-term partnerships, client retention, and business growth. Strong industry connections enhance collaboration, streamline project execution, and drive innovation, ensuring a competitive edge in the market.

Platform-independent design focuses on creating products—whether digital or physical—that function seamlessly across multiple platforms, devices, and environments. By ensuring adaptability, scalability, and cross-platform compatibility, this approach enhances accessibility, usability, and market reach, making products more versatile and future-proof."

This version integrates keywords like "cross-platform compatibility," "adaptability," "scalability," and "future-proof," improving SEO while maintaining clarity. Let me know if you need further refinements

Why Choose MG Techworks?

End-to-End Product Development – From CAD modeling to injection molding and assembly, we handle everything.

High-Quality Materials & Precision Engineering – We use best practices in alloy selection, machining, and mold making.

Industry-Specific Solutions – Expertise in automotive, medical, industrial, and consumer products.

Custom Plastic & Metal Parts – Tailored solutions for replacement parts, prototypes, and mass production.

State-of-the-Art Technology – Utilizing Autodesk Inventor, Revit, and BIM software for advanced product engineering.

End-to-End Product Development – From CAD modeling to injection molding and assembly, we handle everything.

High-Quality Materials & Precision Engineering – We use best practices in alloy selection, machining, and mold making.

Industry-Specific Solutions – Expertise in automotive, medical, industrial, and consumer products.

Custom Plastic & Metal Parts – Tailored solutions for replacement parts, prototypes, and mass production.

State-of-the-Art Technology – Utilizing Autodesk Inventor, Revit, and BIM software for advanced product engineering.

01

02

03

04

Our Expertise

Plastic Injection Molding & Custom Product Development

We provide full-service plastic injection molding with a focus on high-quality components, rapid prototyping, and precision machining. Our expertise extends to resin selection, mold making, and assembly solutions for a variety of industries including automotive, medical, industrial, and consumer products.

Engineering & Prototyping Solutions

From concept to production, our engineering team ensures that every product meets the highest standards of design, performance, and quality control. We specialize in CNC machining, rapid prototyping, insert molding, and silicone injection molding, providing comprehensive support for industrial appl

Manufacturing & Automation

Our manufacturing solutions leverage the latest automation technologies, CNC milling, and 3D printing to enhance mass production, cost efficiency, and precision engineering. With expertise in materials selection, including steel, aluminum, copper, bronze, and titanium, we deliver robust and scalable manufacturing solutions.