In the ever-evolving automotive industry, the design and development of car parts play a pivotal role in shaping the vehicles of tomorrow. A meticulous blend of engineering prowess, innovative design, and advanced manufacturing techniques ensures that each component not only meets functional requirements but also enhances the overall driving experience.

Understanding the Automotive Design Process

The journey of creating a car part begins with a comprehensive understanding of market needs and user expectations. This initial phase involves extensive research to define product goals that align with both consumer desires and business objectives. Subsequently, designers translate these insights into conceptual sketches or wireframes, laying the foundation for the component's form and function.

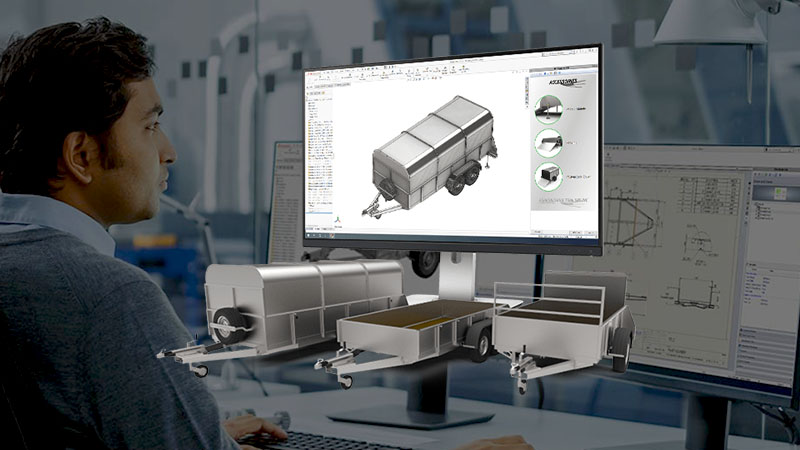

Evaluating the feasibility of these concepts is crucial. This step assesses technical, economic, and manufacturing aspects to ensure that the design is viable and cost-effective. Advanced tools like Computer-Aided Design (CAD) software facilitate the creation of detailed models, allowing for precise simulations and modifications before physical prototypes are developed.

Innovations in Interior Automotive Design

Car interiors have transcended mere functionality to become sanctuaries of comfort, style, and technology. Modern trends emphasize minimalistic designs, ambient lighting, ergonomic layouts, and sustainable materials. These elements collectively enhance the user experience, making the cabin a harmonious blend of luxury and practicality.

Advancements in Manufacturing and Engineering

The manufacturing landscape has been revolutionized by technologies such as 3D printing and Artificial Intelligence (AI). For instance, companies like Czinger are leveraging these advancements to produce high-performance sports cars with unprecedented efficiency. Their approach not only reduces material usage but also accelerates production timelines, setting new benchmarks in automotive engineering.

The Role of Injection Moulding and Assembly

Injection moulding remains a cornerstone in the production of automotive components. This process allows for the mass production of precise and durable parts, ensuring consistency and quality across the board. Coupled with meticulous assembly processes, manufacturers can deliver components that meet stringent industry standards while maintaining cost-effectiveness.

Embracing Kinematic Design and Trim Components

Kinematic design focuses on the motion aspects of components, ensuring that moving parts operate smoothly and reliably. In automotive interiors, this translates to mechanisms like adjustable seats and retractable displays functioning seamlessly. Attention to trim components further elevates the aesthetic appeal, with materials and finishes that resonate with the brand's identity and consumer expectations.

A Commitment to Global Innovation and Excellence

The pursuit of innovation and excellence is a global endeavor in the automotive industry. Manufacturers and designers worldwide collaborate to push the boundaries of what's possible, integrating cutting-edge technologies and sustainable practices. This collective effort ensures that the vehicles of the future are not only efficient and reliable but also environmentally conscious.

Ensuring Uncompromised Quality

Quality assurance is paramount in car parts design and production. Rigorous testing protocols, compliance with international standards, and continuous feedback loops are integral to delivering components that perform flawlessly under various conditions. This unwavering commitment to quality fosters trust and satisfaction among consumers, reinforcing brand loyalty.

Ultimately, the intricate process of designing and manufacturing car parts is a testament to the industry's dedication to innovation, quality, and user-centric design. As technology continues to evolve, so too will the methods and materials used, ushering in a new era of automotive excellence.